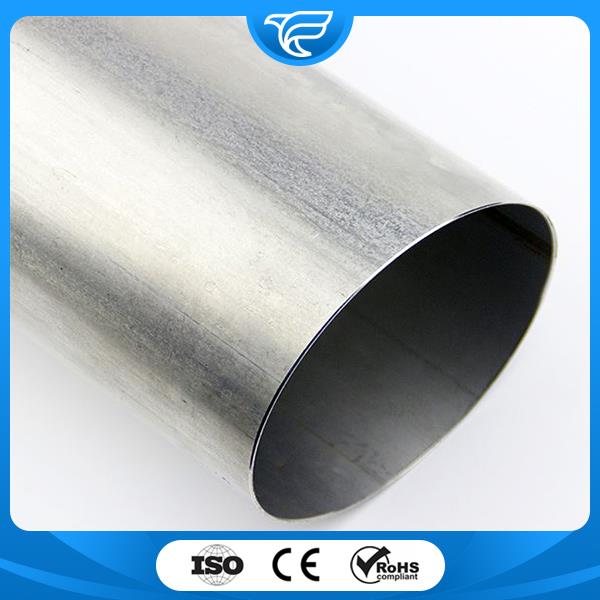

EN 1.4362 Stainless Steel is a low carbon and high alloy stainless steel with a nickel content of less than 4%. The steel contains ferrite - austenite structure, so it is called duplex stainless steel.

In general, the two-phase stainless steel alloy element has a good balance, which contains ferrite elements such as chromium and molybdenum, and contains the austenite element nickel and manganese.1.4362 duplex stainless steel plates can be used instead of 316L and 2205.

1.4362 Stainless Steel Mechanical Performance

Strength of extension: about 700

Yield strength: about 350

Ductility: about 35

1.4362 as a result of the dual phase micro element structure, with excellent mechanical properties and reasonable elongation, in some areas in the ASTM standard, because the sample length on tensile strength tests often to 50 mm, instead of 80 mm.

Therefore, the elongation ratio of A50 is more commonly used than the elongation of A80 (Note: A50 has a higher elongation than A80).

1.4362 Stainless Steel Characteristics:

Corrosion Resistance

In the corrosion resistance of stainless steel, element chromium and molybdenum usually play a major role. The main function of nickel is to combine the manganese copper and make up the austenitic crystal at room temperature, so the nickel is more important than the anti-corrosion in the forming of steel plate.

Because the Cr content of 1.4362 is higher than 316L and does not contain molybdenum, its corrosion resistance is equivalent to 316L, but it is higher than 304.

Welding Property

1.4362 to most familiar way of welding welding (except for welding) if welding need filling agent, is recommended to use high alloy TERMANIT 22 / / 09, since 1.4362 contains about 50% of the ferrite, the grade of steel is more sensitive to hydrogen embrittlement, to dry, so the need when welding filler welding hydrogen in the gas can't overweight.

Spot delivery, including delivering small batches of goods

Provide wide-range and complete materials series products

Cutting plates, including complex shapes of materials and special processing and disposal

Cutting bars and strips

Our application technology expert provide the best material and recommendation

One-stop service